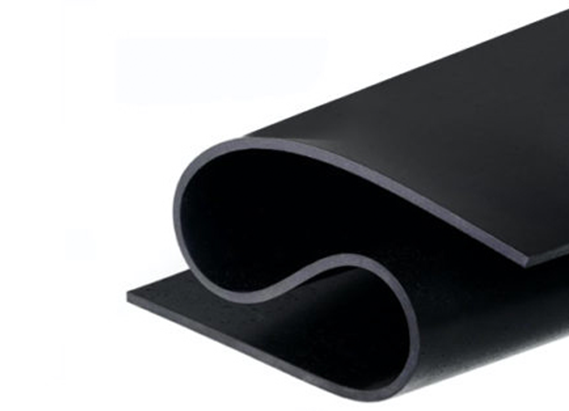

Butyl Rubber

Butyl is a synthetic rubber, also referred to as isobutylene isoprene. Butyl rubber has a variety of uses and applications but its true value is its impermeability to air and gases. Butyl is also very resistant to water and steam, which is why butyl rubber is used in sealants for damp proofing, rubber roof repair and rubber membrane maintenance. First used as tire inner tubes, butyl rubber is now applied to sporting ball bladders, gas masks and protective clothing, vial stoppers, explosives, chewing gum and is even used as an additive in lubricating oils and motor fuels. The addition of small amounts of polyisobutylene in lubricating oils results in a significant reduction of oil mist inhaled by a machine operator.